Supplies replenishment

Replenishing supplies in NDD Orbix is essential to ensure that print outsourcing providers maintain efficient and continuous operation for their customers.

Using high-tech algorithms and with unique precision on the market, the system calculates the quantities required for specific periods through features such as running low alerts and forecast, allowing logistics and purchasing costs to be optimized. This precise and dynamic replenishment gives the provider comprehensive cost management and visibility of the financial health of contracts.

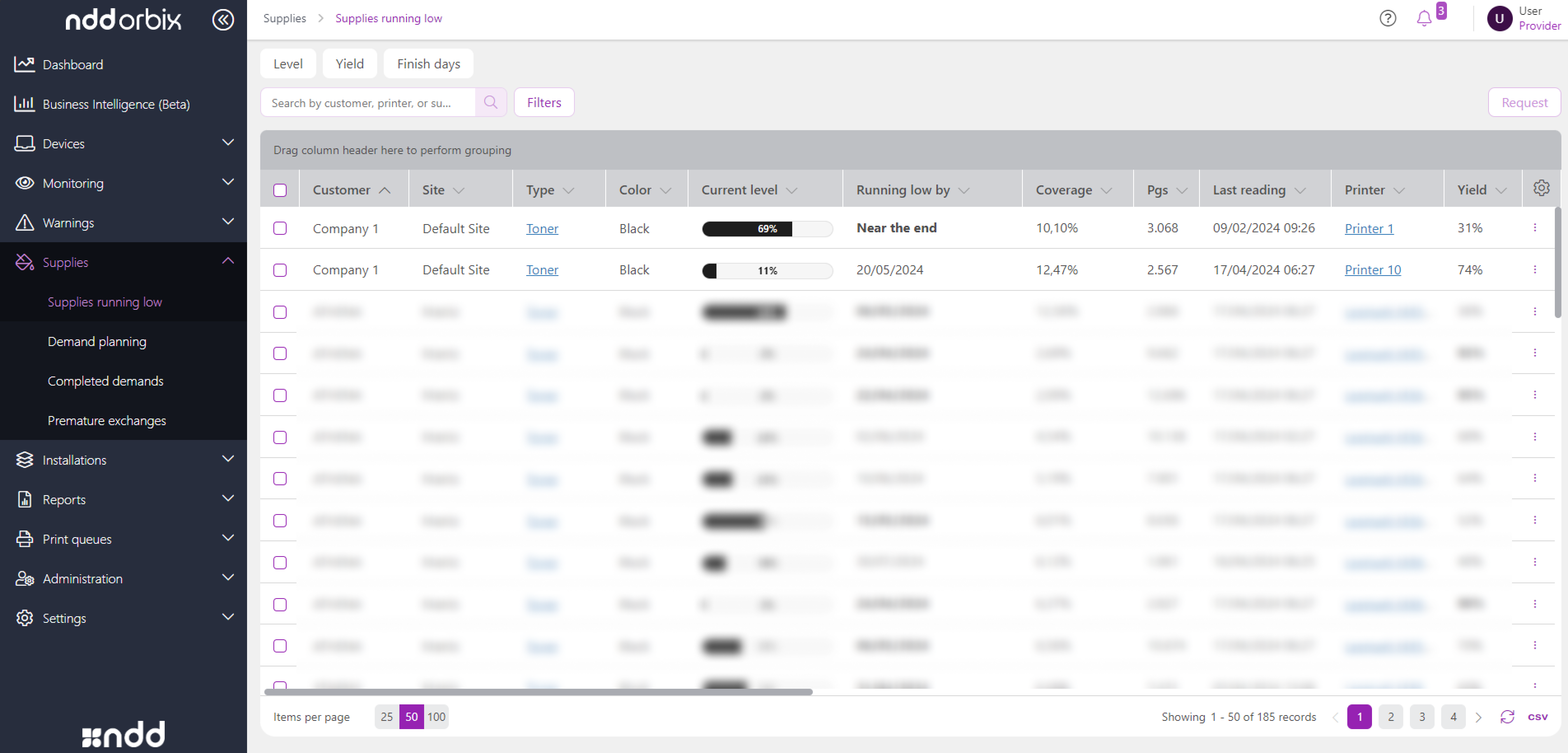

Supply running low alerts and demand generation

The system is prepared to alert situations where supplies are close to running low according to three criteria:

Running low by: the alert is generated when the estimated end date of the supply is equal to or less than 30 days.

Yield: the alert is generated when the supply's yield reaches 80%.

Level: the alert is generated when the supply level is 25% or less.

These criteria are configured by default, but can be adjusted according to the provider's needs, customizing the alert rules according to the operating scenario. To adjust these parameters, see Create printer supply running low alert rule.

Alerts for supplies that are running low

Once the supply running low alerts have been generated, the provider can transform this information into demands to start the replenishment process. This flow can be automated, optimizing the management and execution of replenishments, or it can be managed manually, according to the provider's preference.

To configure the feature, go to Manage printer supply demands.

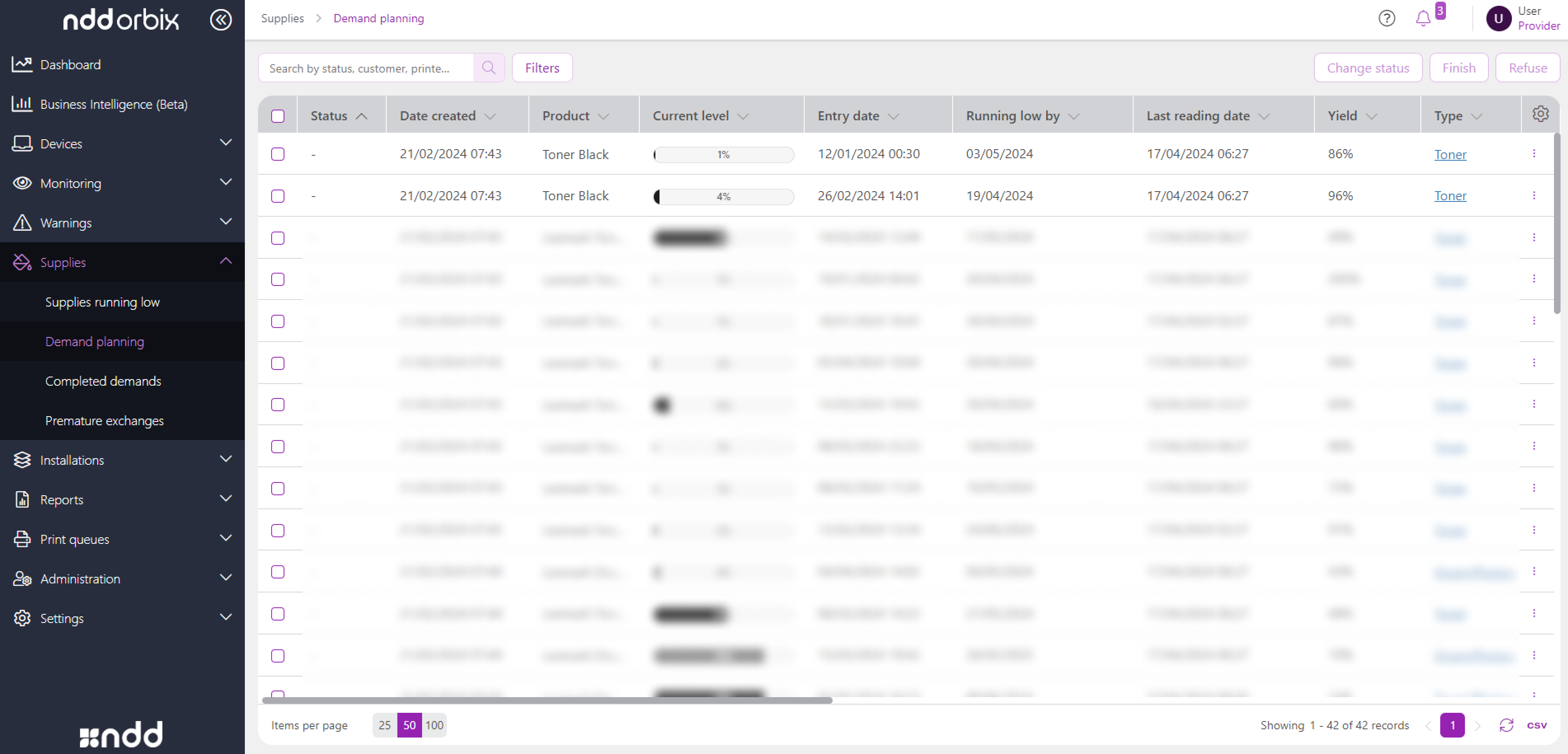

Planning demands

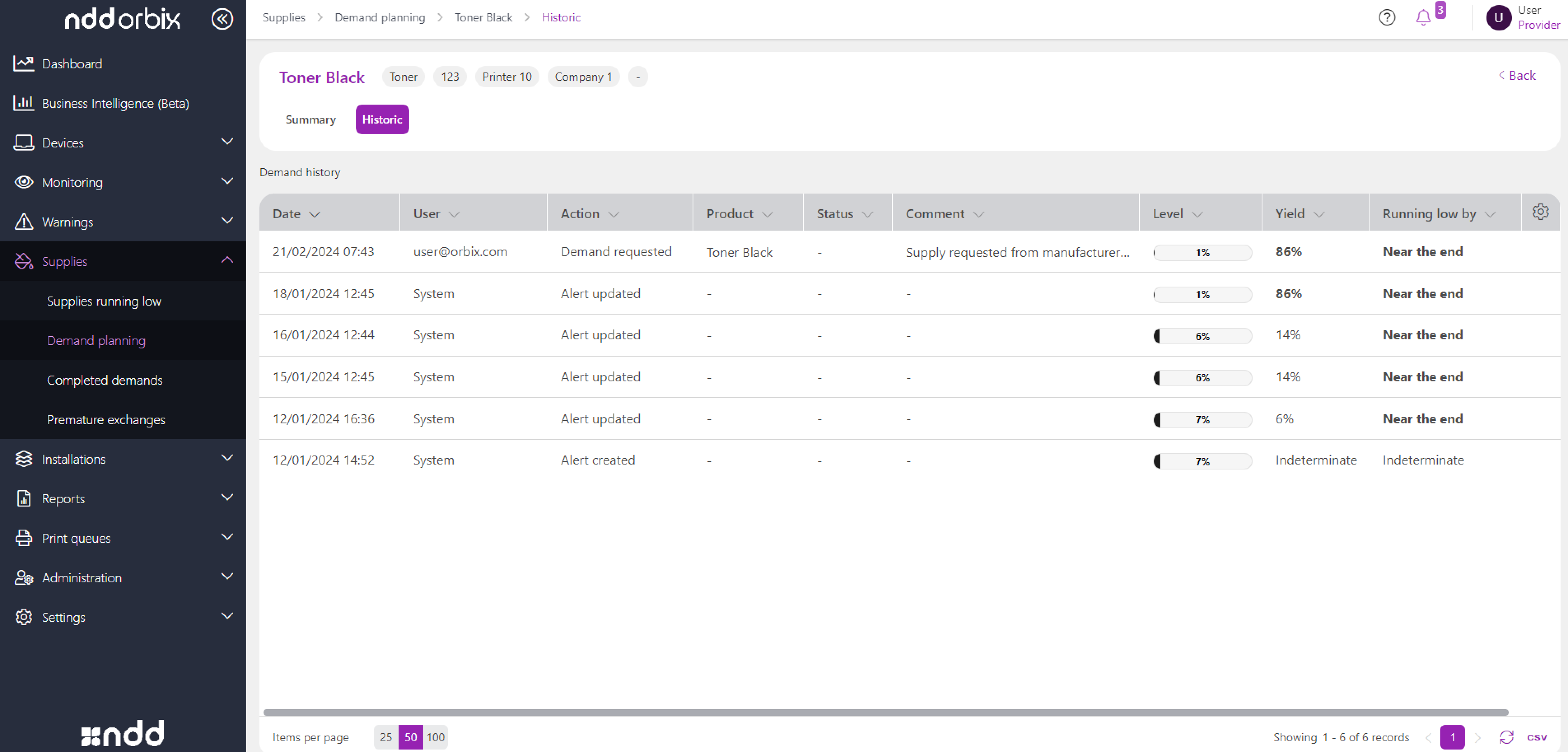

The system also offers complete automation of the supply demand lifecycle, enabling effective management with auditing of actions and detailed status monitoring. This guarantees transparency and control over every stage, from identifying the need to final replenishment.

Demand planning history

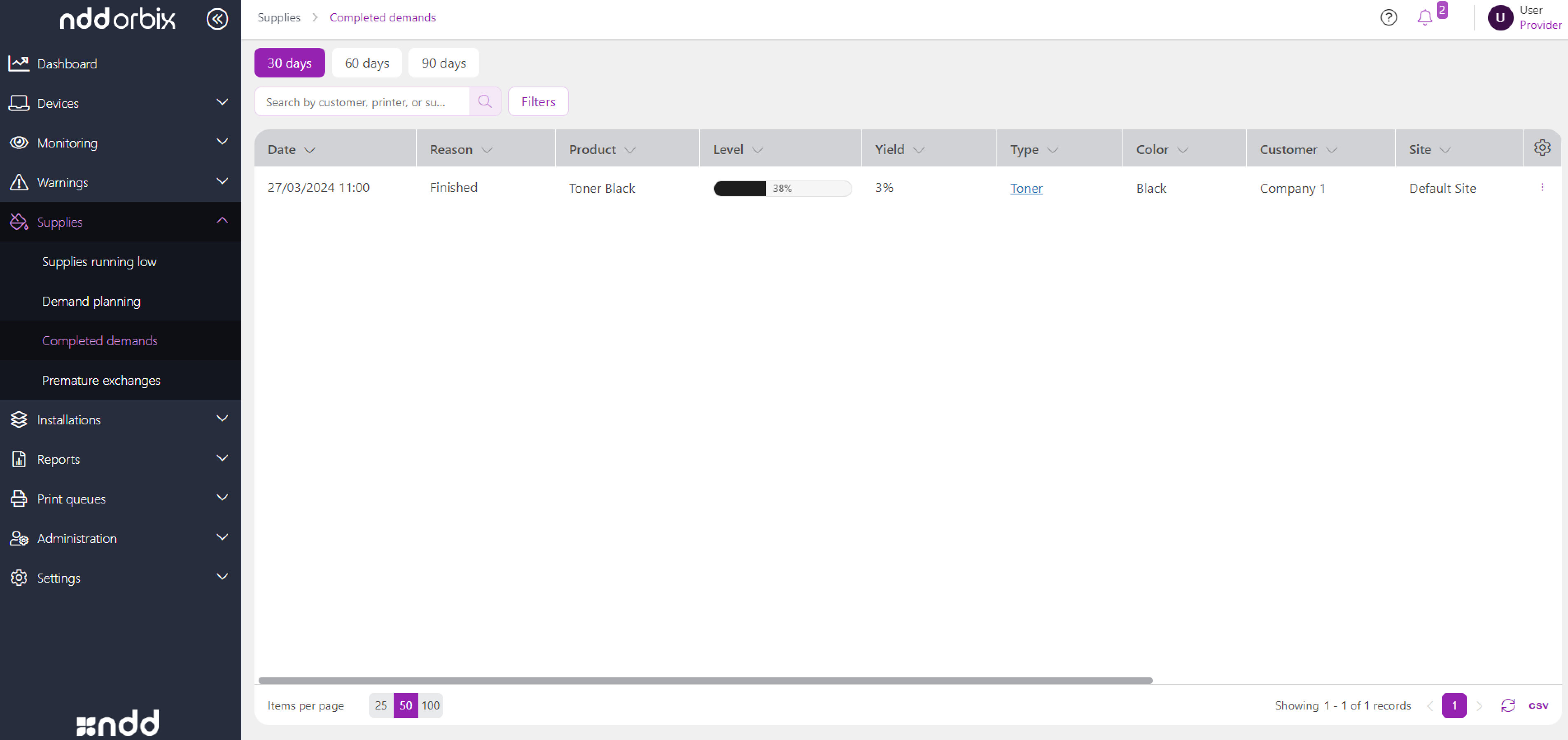

Once demands have been analyzed, they can be:

Finalized: manually, when the customer receives the supply or starts using it, or automatically, when the system identifies the supply change in the printer.

Refused: when the provider assesses that there is no need to replace the supply.

Completed demands

This efficient and detailed demand management ensures that the replenishment process takes place accurately and quickly, avoiding service interruptions and improving operational efficiency.

Supplies forecast

The main objective of NDD Orbix supply forecast is to accurately predict the quantity of supplies needed for printers in a specific period, ensuring efficient stock management and purchase planning. This makes it possible to avoid shortages or excesses of supplies, reduce operating costs and optimize negotiations with suppliers.

The feature uses historical consumption data and current printer usage patterns to calculate future demand for supplies. Based on this analysis, managers and analysts can predict when and how much supply will be needed, ensuring the continuity of operations without interruption. In addition, the feature facilitates strategic purchasing planning, enabling more advantageous negotiations with suppliers by making it possible to purchase on a larger scale.

To configure the feature, go to Generate printer supplies forecast.

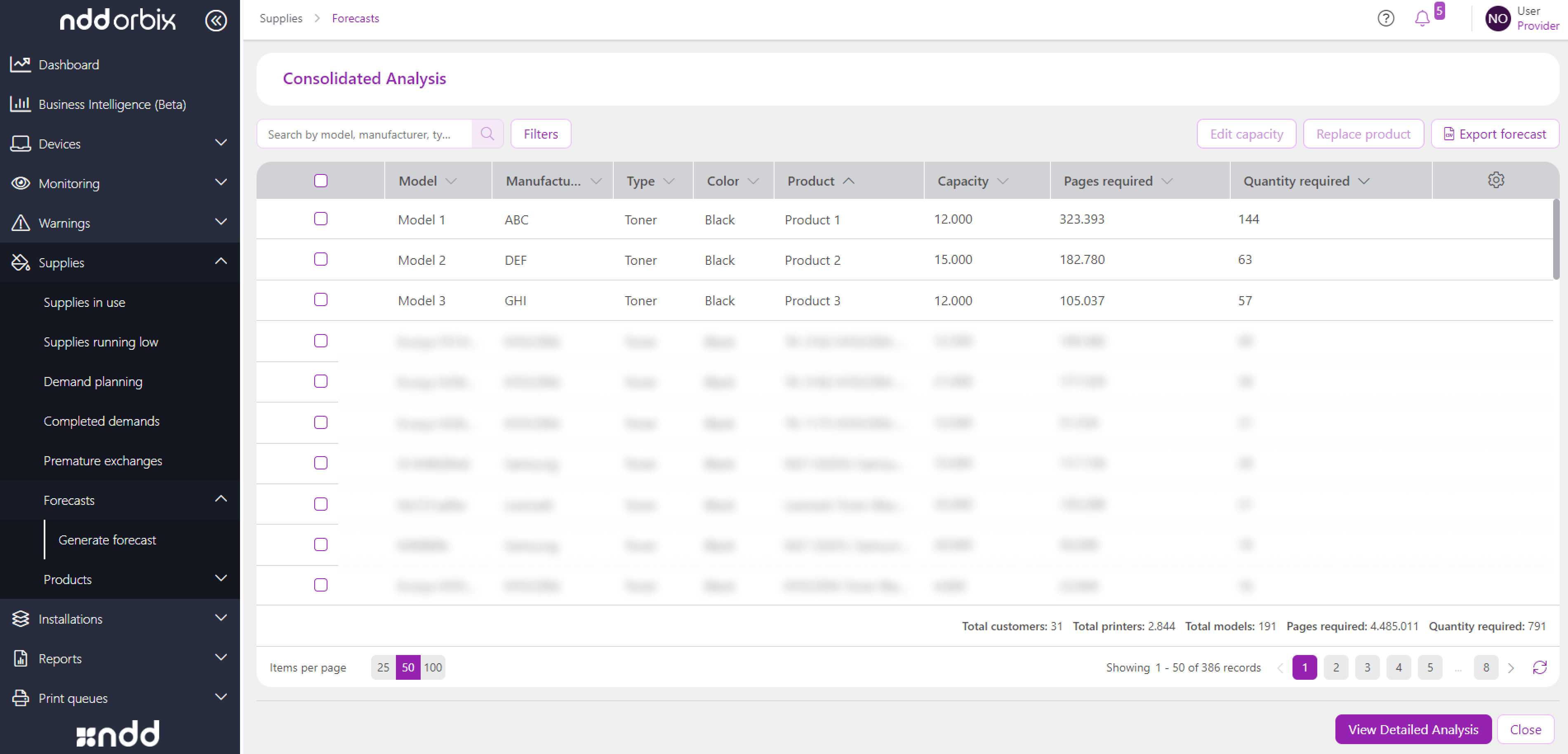

Consolidated analysis view

High-precision prediction: the feature performs a detailed analysis of historical data and current consumption, identifying usage patterns that allow personalized and accurate predictions of supply needs. This enables purchasing, replenishment and strategic planning, providing visibility of costs and helping to avoid both shortages and excess supplies.

Customization of the forecast: the tool offers flexible setting, allowing the forecast to be adjusted according to different periods, printers, manufacturers, models, types and colors of supplies, adapting to the specific needs of each customer or operation.

In terms of flexibility, NDD Orbix allows manual adjustments and substitution of products after generation, giving the provider the freedom to intervene in the forecast and make adjustments as necessary, especially in cases of unexpected changes in consumption or stock.Simulation of scenarios: another differentiator is the simulation of demand scenarios, which makes it possible to predict different situations based on factors such as the volume of printing and the products used. This helps companies to optimize their operations, ensuring that supplies are available at the right time, without wastage.

Data export: the feature makes it possible to export data, making it easier to integrate forecast with other areas of the company, such as the purchasing and finance departments. This contributes to more in-depth analysis and audits, ensuring greater control over the supply replenishment process.

{{component-feedback-article}}