Supplies replenishment for thermal printers

Supplies replenishment in NDD Orbix is essential to ensure that outsourcing printing providers maintain efficient and continuous operation for their customers.

Using high-tech algorithms and with unique accuracy in the market, the system generates alerts for supplies running low, allowing for the optimization of logistics and purchasing costs. This accurate and dynamic replenishment offers the provider comprehensive cost management and visibility of the financial health of contracts.

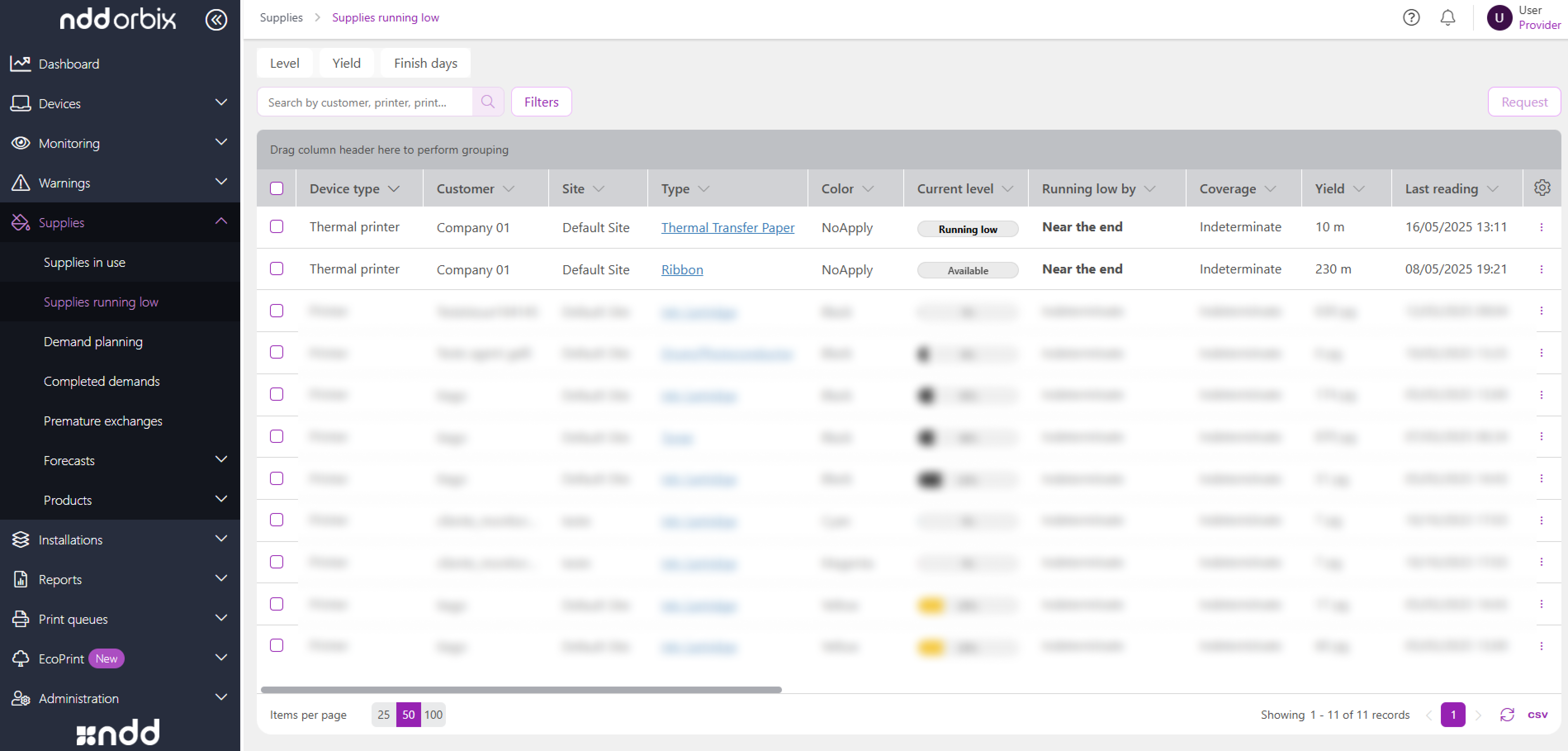

The system is prepared to alert situations of supplies nearing the end based on three criteria:

Running low by: the alert is generated when the estimated end date of the supply is equal to or less than 30 days.

Yield: the alert is generated when the supply's yield reaches 80%.

Level: the alert is generated when the supply level is low.

These criteria are configured as default, but can be adjusted according to the provider's needs, customizing the alert rules according to the operating scenario. To adjust these parameters, see Create thermal printer supply running low alert rule.

Alerts for supplies that are running low

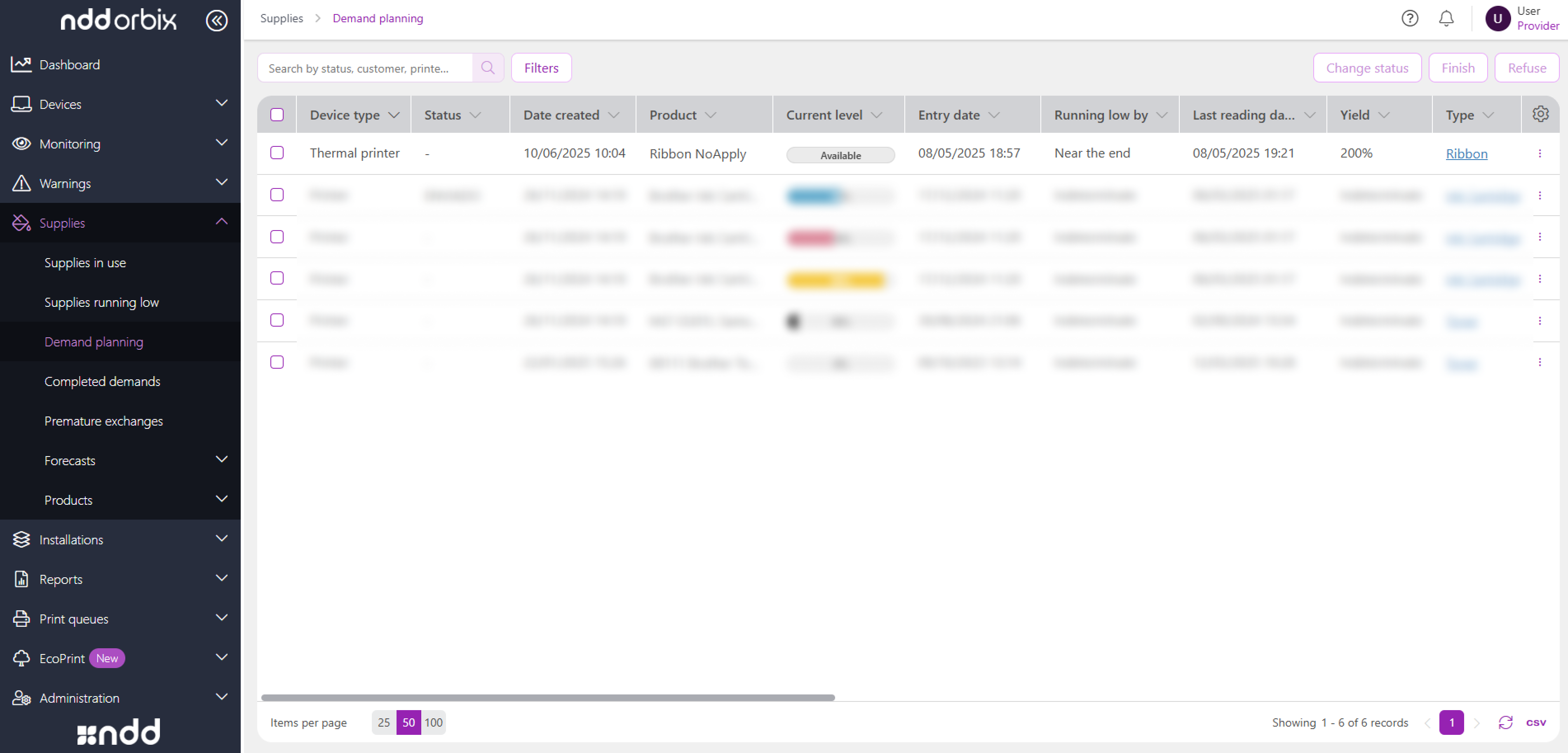

After the supply running low alerts are generated, the provider can transform this information into demands to start the replacement process. This flow can be automated, optimizing the management and execution of replacements, or it can be managed manually, according to the provider's preference.

To configure the feature, access Manage thermal printer supply demands.

Planning demands

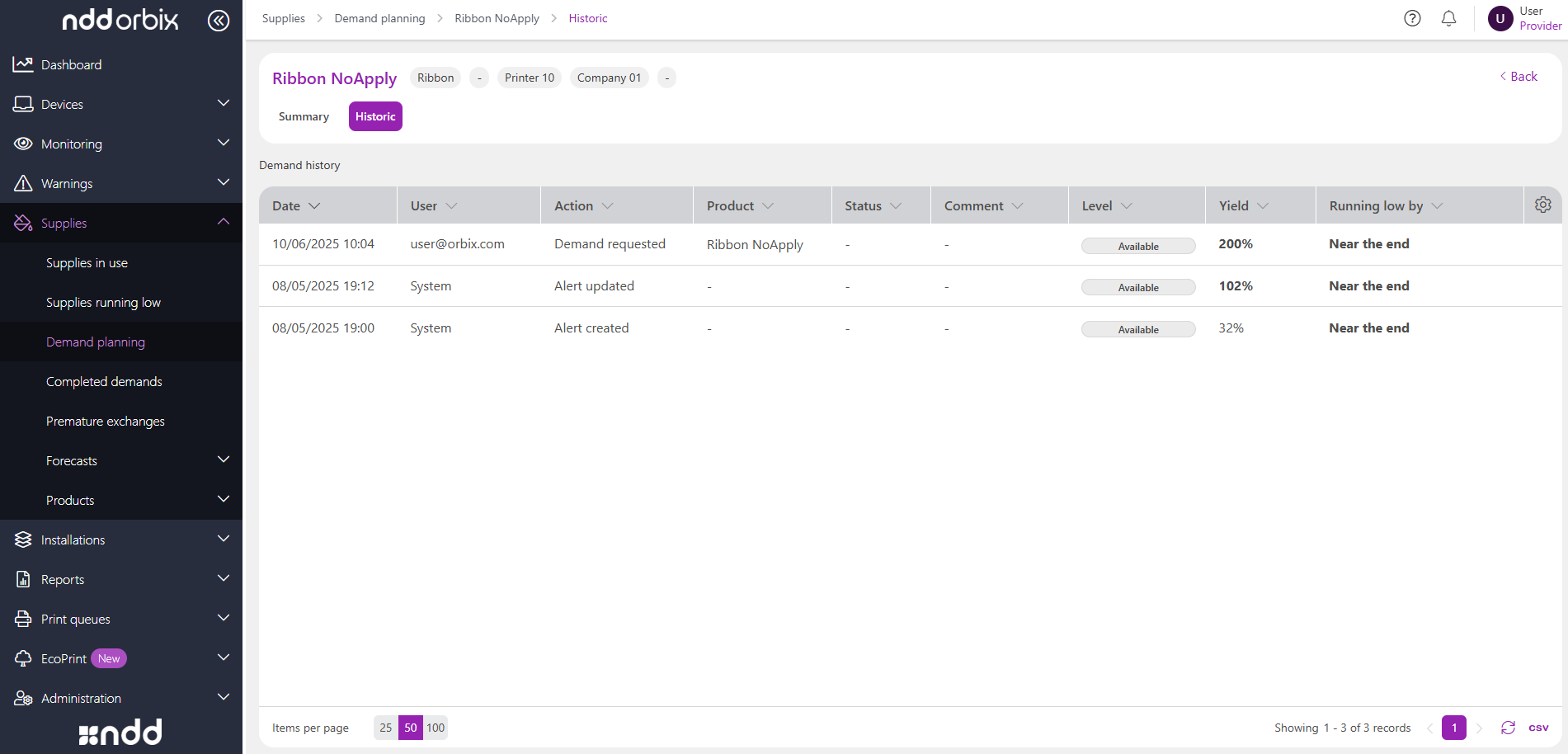

The system also offers complete automation of the supply demand lifecycle, allowing for effective management, with action auditing and detailed status tracking. This ensures transparency and control over each stage, from identifying the need to final replenishment.

Demand planning history

After analyzing the demands, they can be:

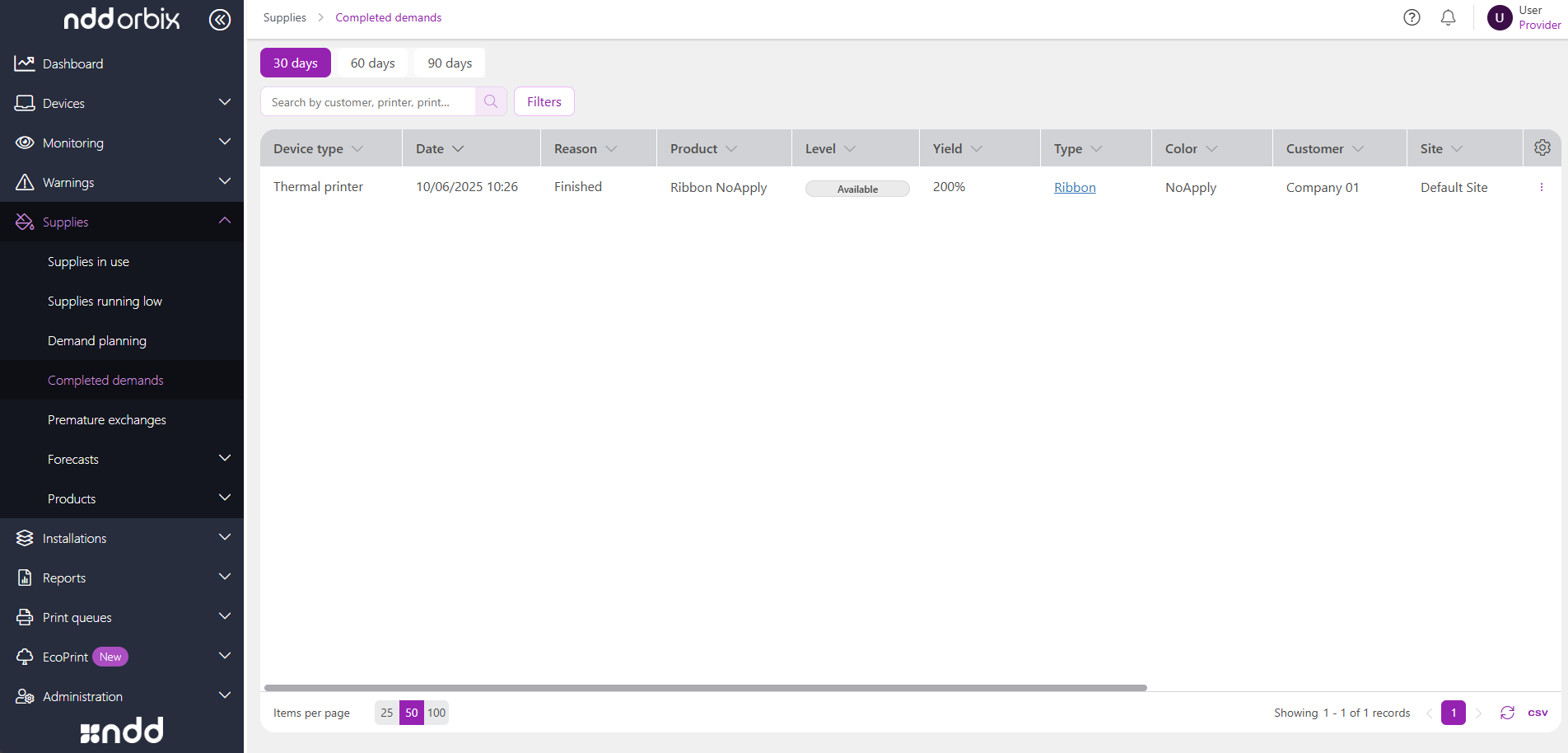

Finalized: manually, when the customer receives the supply or starts using it, or automatically, when the system identifies the exchange of the supply in the printer.

Refused: when the provider assesses that there is no need to replace the supply.

Completed demands

This efficient and detailed management of demands ensures that the replenishment process occurs accurately and quickly, avoiding service interruptions and improving operational efficiency.